1

CUTTING TOOL MATERIALS

Somta cutting tools are manufactured from the finest steel

available. The heat treatment process is controlled by our

Metallurgical laboratory using advanced computerised and

electronic instrumentation. High Speed Steel contains various

elements such as Molybdenum, Tungsten, Cobalt and Vanadium

and must be specially heat treated to produce the ideal

combination of strength, toughness and wear resistance.

SOMTAproducts are manufactured from one of the following High

Speed Steels depending on the product and application.

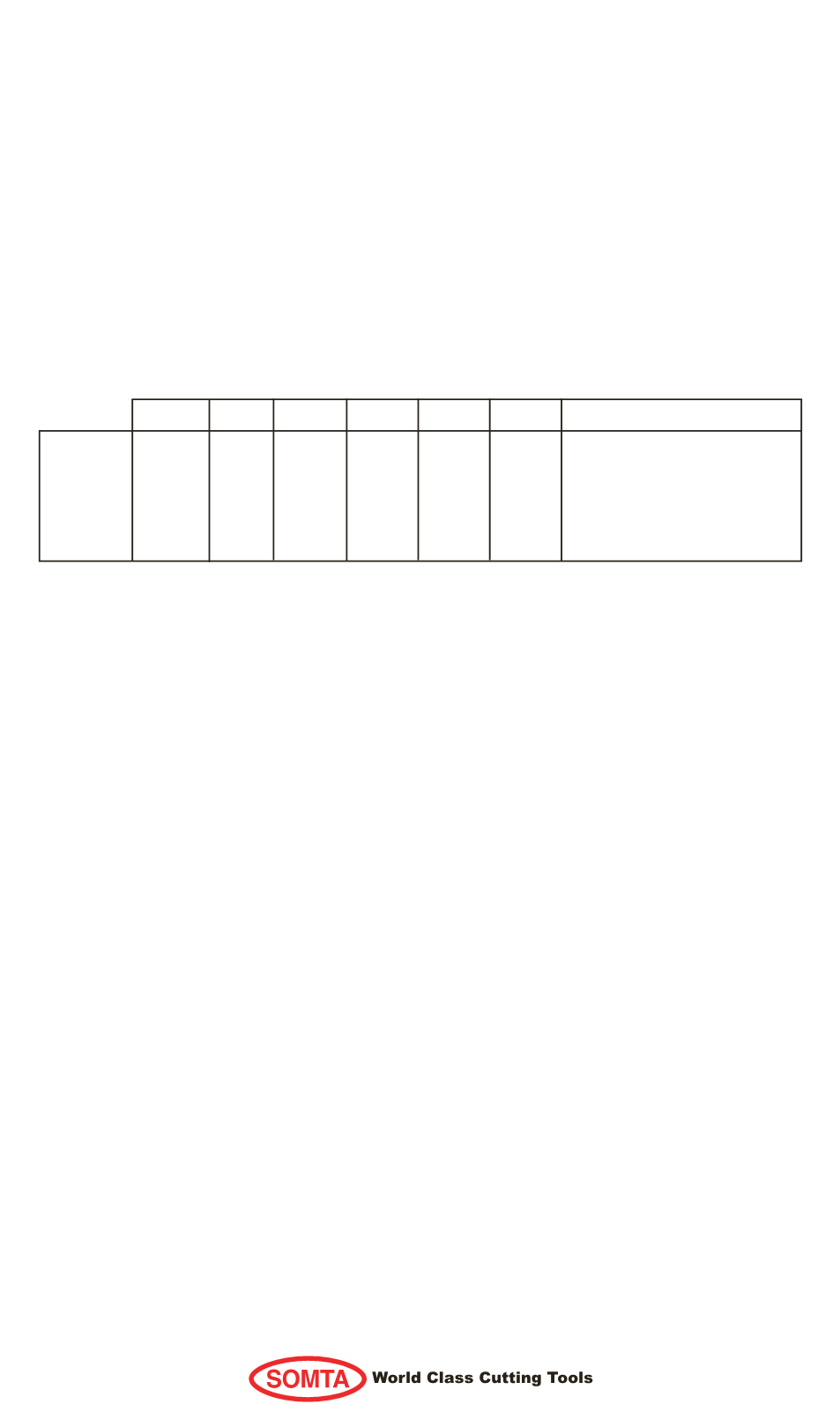

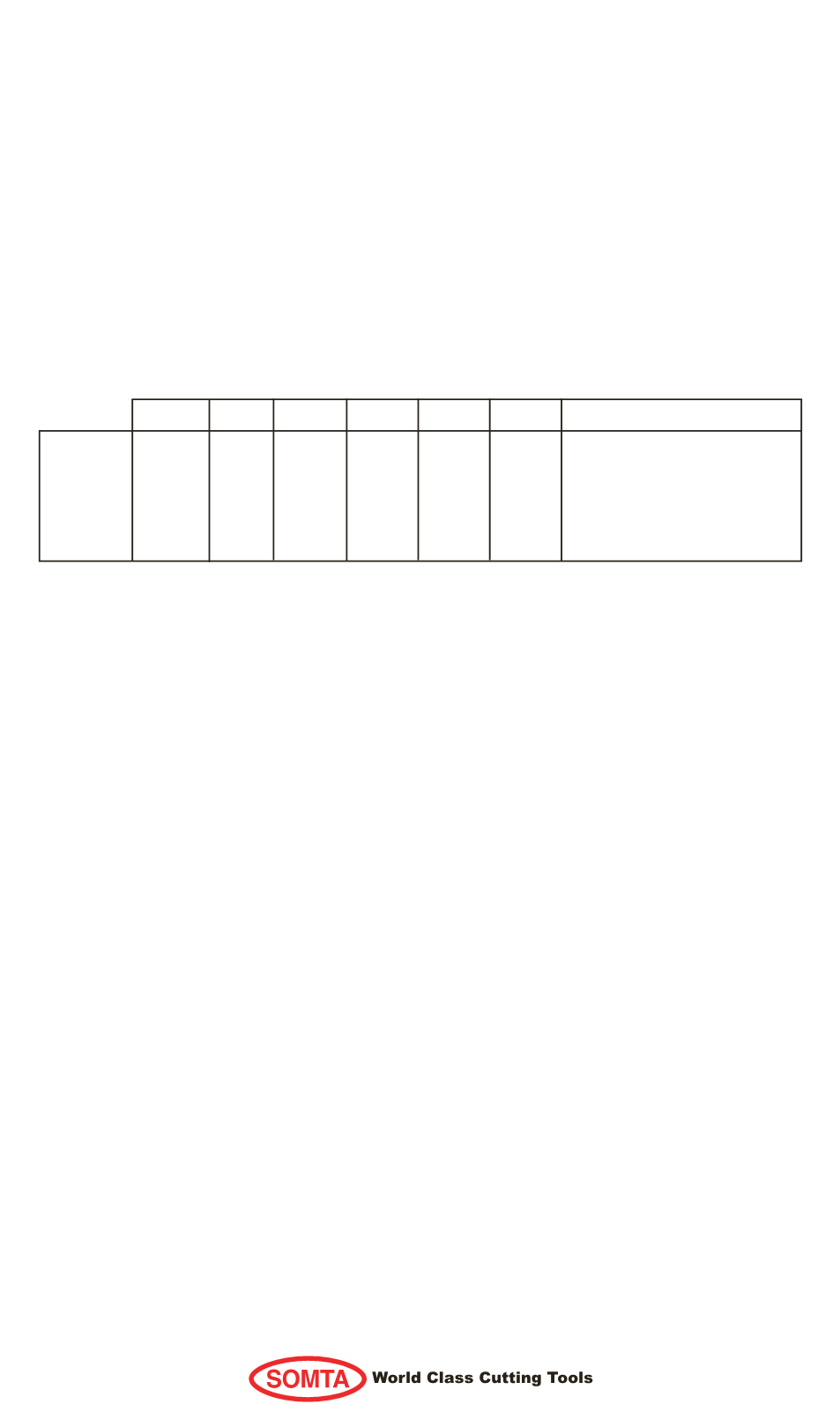

C Cr W Mo V Co Hardness (HRC)

M2 0.9 4 6 5 2 - 63 - 65

M35 0.9 4 6 5 2 5 64 - 66

M42 1.1 4 1.5 9.5 1 8 66 - 68.5(70)

M9V 1.25 4.2 3.5 8.5 3 - 64 - 66

M2 is the standard High Speed Steel and is used where toughness

is important, together with a good standard of wear resistance and

red hardness.

M35 is a development of M2 and contains 5% cobalt which gives

improved hardness, wear resistance and red hardness. It may be

used when cutting higher strength materials.

M42 can be heat treated to very high hardness levels of up to 70

HRC (1 000 HV) although normally a slightly lower figure will be

employed to retain toughness. This steel is ideal for machining higher

strengthmaterials andwork hardening alloys such as stainless steels,

nimonic alloys etc. Despite its high hardness, M42 has good

grindability characteristics due to lower vanadium content.

M9V material is mainly used in the manufacture of machine taps

because of its good wear resistance, good grinding capabilities, high

hardness and excellent toughness.

Cutting tools may shatter

eye protection should be worn